Sizing a Solar Panel System

INTRODUCTION

Whether you simply want to generate your own clean energy or save money on your electric bill, investing in a solar power system is a smart choice. Once you have made this choice or have chosen to explore the options, it is important to make sure that your solar photovoltaic (PV) system is properly sized to ensure you will have enough power to fit your needs. Unfortunately there is no such thing as one size fits all when it comes to solar; as everyone’s needs and usage varies as does the amount of sun depending on your geographic region. The intent of this article is to help properly size your solar power system and give you a general idea of what may be involved to generate your own clean energy.

POWER CONSUMPTION

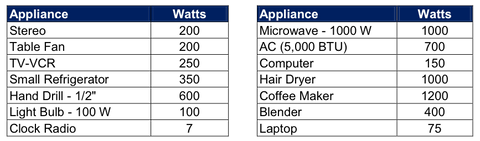

The first step to properly size your system is to determine what appliances and/or devices you are looking to power or if you are considering powering an entire household you can review your current electricity bills and average out your actual consumption; typically presented in kilowatt hours. If your consumption is large, you may want to offset some of the energy with your own production. While 100 percent seems appealing, it may not be financially feasible or practical due to space constraints. As a general rule, 100 square feet of solar panels will generate 1 kilowatt (kW) of electricity. An alternative is to figure out exactly how many watt-hours per day of energy you'll need. In order to this you will need to prepare a list of all your appliances and devices you would like to power and how many hours per day each device will be operational. Once the list is prepared, the peak power draw of each device must be determined. Some devices may provide this information (Watts) or there are reference charts available; see “Typical Power Consumption” table. Alternatively, Watts is equal to Amps x Volts, so if you have this information you can determine the Watts.

WATTS VS. WATT HOURS

Keep in mind that Watts is an instantaneous power measurement, not to be confused with Watt hours, which is the actual energy consumption. Watts must be multiplied by estimated run time to determine energy consumption. A good analogy would be speed vs. distance. Watts are equivalent to speed, whereas Watt hours would be the distance. In order to determine how many panels are needed you need to know the “distance.” Power consumption is measured in Watt hours (Wh) per day. To do this, you will use the total power draw and multiply that by the amount of hours the device will be powered per day. Below are some examples

1) Lighting

If you have two 40W light bulbs that you plan on running for 8 hours per day, you would take the wattage of each bulb, multiply it by the number of bulbs and multiply that by the number of hours of run time per day.

2 bulbs x 40 W x 8 hours/day = 640 Wh per day

2) Pumps and Motors

If you plan to run a 1 horse power (hp) pump for one and a half hours per day you would first convert the hp into Watts: 1hp = 745W, Then multiply that by number of hours of run time per day.

1 pump x 745 W x 1.5 hours/day = 1118 Wh per day

3) Miscellaneous Electronics

1 laptop x 75 W x 4 hours/day = 300 Wh per day 1 oven x 1000 W x (10/60) hours/day = 167 Wh per day 1 clock x 7 W x 24 hours/day = 168 Wh per day 300 Wh + 167 Wh + 168 Wh = 635 TOTAL Wh per day

4) Battery Charging

If your plan is to keep a battery bank charged, first add up the charge capacity of all the batteries in your system. This is presented in Amp hour (Ah) and is usually shown on the side of the battery. It is recommended to only discharge 50% of the charge capacity of the battery bank so we will only factor in half of the total charge capacity. As an example, an RV with two 12V 80Ah batteries would have a 160Ah battery bank; half of that would equal to 80Ah. To convert Ah into Watt hours, multiply the charge capacity of the battery bank by the battery voltage.

2 Batteries x 80 Ah/battery x 0.50 x 12 V = 960 Wh per day

TYPICAL POWER CONSUMPTION

PANEL REQUIREMENTS

On an average day, a single 100W panel will produce about 400 Watt hours (Wh) of charge. This figure will vary depending on the actual time of sun exposure, the orientation of the panel into the sun, and any obstructions. In the summer months production will be higher than in the winter and on bright sunny days the output will be higher than on cloudy days.

A single 100W panel will have an average daily production of: 400 Watt hours (Wh) = 0.40 kilowatt hours (kWh) = 33 Amp hours (Ah)

After determining your power consumption as shown in the previous section, divide that number by the production of a single panel. Because you always want to be sure to have enough power, it is recommended to round all answers up to the next whole number.

1) Lighting Example:

Two 40W Light Bulbs for 8 hours per day; 2 bulbs x 40 W x 8 hours/day = 640 Wh per day

640 Wh per day / 400 Wh per panel per day = 1.6 panels = 2 panels

2) Pumps and Motors example:

One 1hp pump for 1 1/2 hour per day; 1 pump x 745 W x 1.5 hours/day = 1118 Wh per day

1118 Wh / 400 Wh per panel = 2.8 panels = 3 panels

3) Miscellaneous Electronics example:

One clock radio for 24 hours, one laptop for 4 hours, and a microwave oven for 10 minutes per day; 300 Wh (laptop) + 167 Wh (oven) + 168 Wh (clock) = 635 TOTAL Wh per day

635 Wh / 400 Wh per panel = 1.6 panels = 2 panels

4) Battery Charging example:

Two 12V 80Ah batteries per day; 2 Batteries x 80 Ah/battery x 0.50 x 12 V = 960 Wh per day

960 Wh / 400 Wh per panel = 2.4 panels = 3 panels

POWER INVERTERS

Solar panels produce a DC voltage power source that is typically wired to a charge controller and then into a battery bank. If you are looking to power typical household AC powered appliances/devices (eg: 120VAC), the use of a Power Inverter is required. The inverter will connect directly to the battery and convert the DC battery power into 120 VAC household power. The Inverter will also provide the typical AC 3-prong receptacles to plug your device(s) into.

When selecting an inverter it is important to know the total Wattage of your load(s). These are the values presented in the section “Typical Power Consumption”. It is recommended to have an inverter sized 120% of the maximum load that will be applied. For each example, you can use an inverter greater than or equal to the total watts provided.

1) Lighting example:

2 Bulbs x 40 W x 1.2 = 96 Watt inverter or greater

2) Pumps and Motors example:

One 1hp pump

1 pump x 745 W x 1.2 = 894 Watt inverter or greater

3) Misc. Electronics example:

One 75W laptop, one 1000W microwave, and one 7W clock.

(1 laptop x 75 W) + (1 microwave x 1000 W) + (1 clock x 7 W) = 1082 Watt inverter or greater

4) Battery Charging example:

Two 80Ah batteries

No inverter needed (battery provides a DC source)

PURE SINE VS. MODIFIED SINE

There are two basic styles of inverters available: modified sine wave and pure sine wave. Pure sine wave inverters are used to operate sensitive electronic devices that require high quality waveform with little harmonic distortion. In addition, they have high surge capacity which means they are able to exceed their rated wattage for a limited time. This enables power motors to start easily which can draw up to seven times their rated wattage during startup. Virtually any electronic device will operate with the output from a pure sine wave inverter.

Modified sine wave inverters (modified square wave or step wave) approximate a pure sine waveform. Modified sine wave inverters are designed to satisfy the efficiency requirements of the photovoltaic system while being less expensive than pure sine waveform inverters. These inverters are capable of operating a wide variety of loads; electronic and household items including but not limited to TV, VCR, and satellite receiver, computers, and printers.

BATTERY BANKS

It is recommended to use deep cycle batteries for solar powered systems. A deep cycle battery is designed to be charged and discharged regularly, unlike standard car batteries that are meant to hold a somewhat constant charge. Deep cycle batteries come in many forms including lead acid, sealed AGM and Lithium Ion. A typical deep cycle battery can discharge about 50% of its Amp hour (Ah) capacity without adversely affecting the battery performance

If you need a battery to store 1200Wh of charge you first need to convert the 1200Wh to Ah by dividing it by 12V (the voltage of a battery) to get 100Ah. Since the battery can only discharge 50% of its capacity, you must double the 100Ah and use a 200Ah battery bank to store 1200Wh of usable power.

1) Lighting example:

Two 40W Light Bulbs for 8 hours per day; 2 bulbs x 40 W x 8 hours/day = 640 Wh per day

640 Wh / 12 V = 53 Ah x 2 = 106 Ah battery bank

2) Pumps and Motors example:

One 1hp pump for 1 1/2 hour per

1118 Wh / 12 V = 93 Ah x 2 = 186 Ah battery bank

3) Misc. Electronics example:

One clock radio for 24 hours, one laptop for 4 hours, and a microwave oven for 10 minutes per day; 300 Wh (laptop) + 167 Wh (oven) + 168 Wh (clock) = 635 TOTAL Wh per day

635 Wh / 12 V = 53 Ah x 2 = 106 Ah battery bank

NOTE: The values shown above represent the power requirement for a single day’s use. If additional days of back-up/reserve power are required; the value provided must be multiplied by the required number of days of reserve power.

BATTERY CONNECTIONS:

Multiple batteries can be connected to each other to increase the Amp Hour storage capacity of your system.

Batteries have a limited life and the number of times a battery is cycled (charged and discharged) will be a factor in the life expectancy of the battery. Having many batteries wired together will increase the life of all the batteries in the bank and will not affect the performance.